When selecting an underwater inspection camera, various factors need to be comprehensively considered to ensure it can meet actual inspection requirements. Here are the key considerations:

Clarify the usage environment and depth: Different underwater scenarios have significantly different requirements for cameras. Firstly, determine the type of water area for inspection, whether it is freshwater (such as lakes, rivers, reservoirs) or seawater. Seawater is more corrosive, so the camera's material and protective performance need to be better. At the same time, the maximum diving depth must be clarified, and the camera's waterproof rating must match it. Common waterproof ratings such as IP68, but the specific pressure it can withstand should correspond to the actual depth to avoid equipment damage due to insufficient pressure.

Pay attention to camera performance parameters: Resolution is a core factor affecting imaging quality. High-definition resolutions (such as 1080P, 4K) can present underwater details more clearly, facilitating the discovery of minor issues. The lens angle is also important. A wide-angle lens can expand the shooting range, suitable for large-scale inspections; while a telephoto lens is suitable for observing specific targets at a long distance. In addition, in underwater environments with poor lighting conditions, the camera's low-light performance is crucial. It is necessary to choose products with high sensitivity (ISO) and infrared night vision functions to ensure clear images can be captured in dim environments.

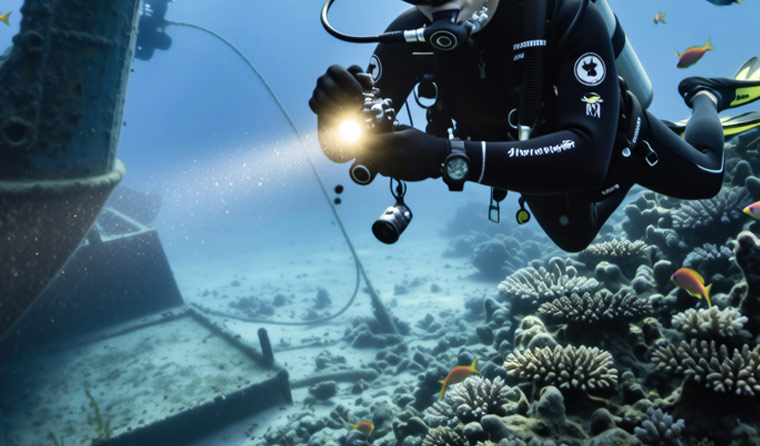

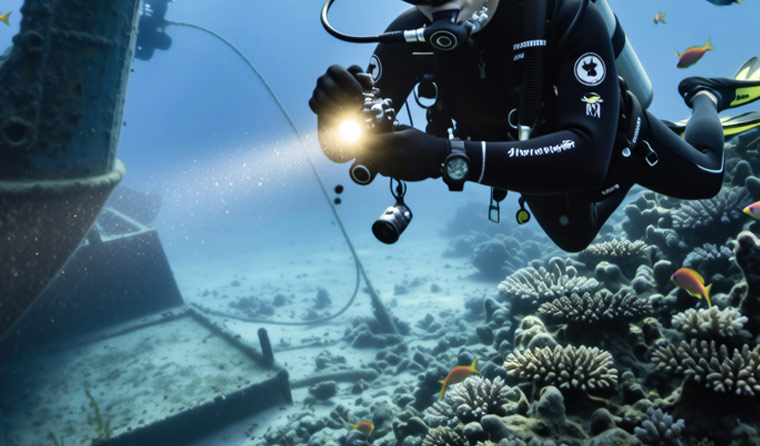

Consider the practicality of functional configurations: Select appropriate functions according to inspection needs. For example, whether real-time transmission function is required to allow operators to view inspection images in real-time on the water surface; whether video recording and photography functions are needed to record inspection data and retain evidence. Some cameras are also equipped with laser ranging functions, which can help measure the distance of underwater objects and improve the accuracy of inspections. In addition, whether it supports external devices (such as lights, robotic arms) should also be considered to enhance the camera's applicability.

Attach importance to durability and protection capabilities: The underwater environment is complex, so the camera must have good durability. The shell material should be corrosion-resistant and impact-resistant, such as stainless steel, titanium alloy, etc., to cope with underwater collisions and chemical corrosion. At the same time, the sealing performance must be reliable to prevent water from entering the equipment and causing short circuits. In addition, the camera should be able to adapt to a certain range of water temperature changes to avoid affecting normal operation due to sudden temperature changes.

Evaluate operational convenience and portability: The simplicity of operation directly affects inspection efficiency. The camera's control system should be intuitive and easy to understand, allowing operators to master it quickly. For cameras that need to be held by hand, weight and grip feel are important; an overly heavy device will increase the operational burden. If it is used for underwater robot mounting, it is necessary to consider whether the camera's size and installation method are suitable. Battery life cannot be ignored either. It is necessary to choose a product with sufficient battery life according to the duration of the inspection task, or equip it with a spare battery.

Refer to brand reputation and after-sales service: Choosing underwater inspection cameras from well-known brands is usually more reliable. These brands have more advantages in technological research and development and quality control. At the same time, a sound after-sales service system is crucial, including product warranty, maintenance support, and technical consultation, which can promptly solve problems when the equipment has issues and reduce inspection delays caused by equipment failures.